Introduction of cooking equipment

1. Main structure and working principle

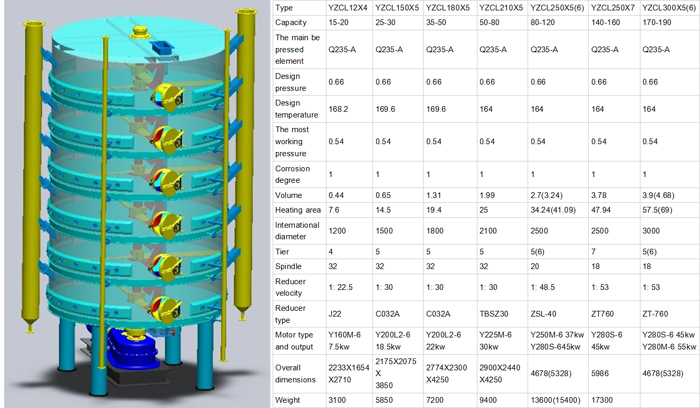

The ZCL type cooking equipment is a cylindrical multi-layer equipment.

This machine is composed of a pot body, steam inlet pipeline, condensate pipeline, stirring device, reducer, automatic feed door, and discharge port.

The pot body is divided into 5-8 layers, and each layer has an interlayer at the bottom and sides of the pot. The steam entering each layer is adjusted by the valve of each layer to control the temperature of the material. In order to make the material embryo steam and fry uniformly, each layer is Equipped with a stirring scraper. The scraper is driven by the main shaft that penetrates each layer, and the main shaft reducer and coupling are connected with the motor. A direct nozzle is installed under the scraper of the first layer of steamer, and it rotates with the scraper, so that direct steam is evenly sprayed into the material.

This machine is equipped with exhaust devices on each layer (except the first layer) to remove the gas that evaporates from the raw material during the steaming process. Each layer of the steaming and frying pan is equipped with an automatic feed door to control the discharging. The outside is equipped with a material layer pointer to indicate the level of the material layer. The bottom of the bottom pot is equipped with an adjustable discharge door.

In order to facilitate the maintenance, each floor is equipped with maintenance access to Yemen, and the doors are equipped with small doors for observation and sampling.

2. Instructions

1). Check each layer of steamer before driving to remove debris. Then adjust the material door to the required position. Generally, the first and second layers are filled with no less than 80% to achieve the purpose of steaming embryos, and the rest is reduced layer by layer, about 40-50%, so that the water vapor during the frying process can be reduced. discharge.

2). Turn on the electric motor to run dry and check whether it is running normally.

3). Before feeding, open each condensate valve first, and then slowly open the steam inlet valve to drain the condensate until the boiler body heats up. At the same time, fix each layer of the material door in the closed position, and then start feeding and spray direct steam. When the material layer of the first layer of steamer reaches the predetermined height, the unloading door of this layer is opened, and the material embryo is slowly placed on the second layer; according to the above method, layer by layer until the fifth layer. At this time, the gates of each layer are working normally. When the fifth layer of material reaches the predetermined height, it will start discharging and check the moisture and temperature of the discharging material, and adjust according to the process requirements and in-between.

4). During the operation, pay attention to adjusting the pressure of direct steam and indirect steam and the size of the exhaust valve to control the temperature and moisture of the raw material in the pot to meet the technological requirements.

5). When stopping, stop feeding first, discharge all layers of material, close the water inlet valve and steam inlet valve of each layer at the same time, and finally turn off the motor to stop. If an emergency stop occurs for some reason, immediately turn off the motor, stop feeding the steamer, and close the water inlet valve and steam inlet valve, and then remove all the material embryos in the pot from the inspection hole. After the inspection is ready, press the start button again. Procedures, restart feeding.