Palm oil refining

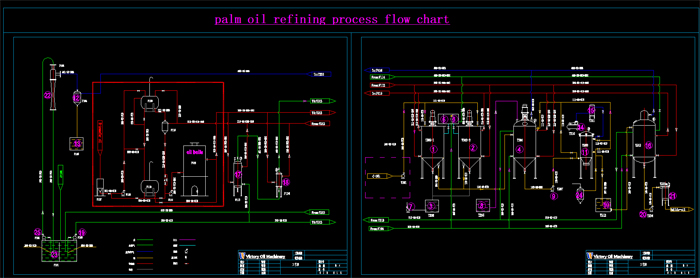

1. Process flow

Crude palm oil →heating→acid refining→alkali refining→water washing 2~3 times→drying and dehydration→bleaching/decolorization→deodorization

2. Process description

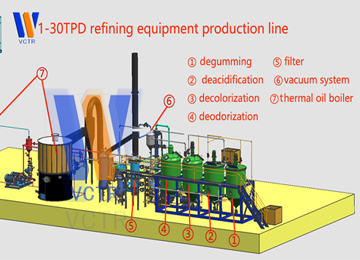

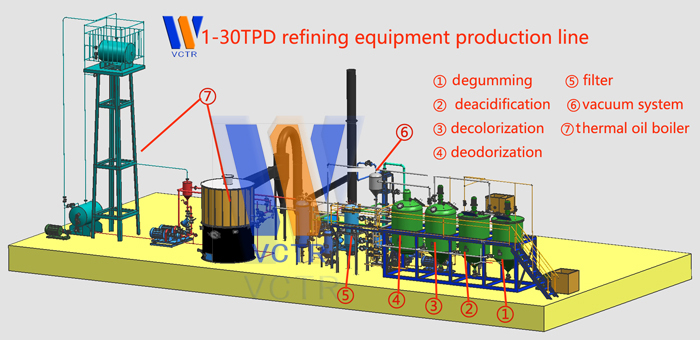

a. Deacidification

The FFA contained in crude palm oil are not conducive to the storage and use of oils, and must be neutralized with alkali and then removed. Therefore,for the palm oil refining deacidification is also called alkali refining. It is based on the content of FFA contained in the crude oil, adding an appropriate amount of alkali solution, and after fully stirring, the alkali and FFA will form soapstock and be removed. At the same time, the soapstock can also absorb impurities and pigments remaining during hydration and degumming. After full alkali refining, the content of free fatty acids can be reduced to 0.01%-0.03%, and the content of phospholipids is about 0.0015%.

b. Alkali refining

For the palm oil refining ,The alkali refining operation method is divided into low temperature concentrated alkali method

Ⅰ. Low-temperature concentrated alkali method operation

Adjust the oil temperature to 20~30℃, then add the 20~30Be lye in 5~10 minutes and stir for about 20~60 minutes under the condition of 60 rpm, and observe the formation and separation of soap particles after the reaction. Slowly increase the temperature, about 1°C per minute. When the temperature reaches 60°C, stop stirring and start to stand still to allow the soapstock to settle. It usually takes 6-8 hours, and then release the soapstock.

Ⅱ. High temperature light alkali method operation

For the palm oil refining,First, determine the alkali concentration according to the acid value of crude oil

| Crude oil acid value | <3 | 3~5 | 5~7 | 7~10 | >10 |

| Alkali concentration Be | 10 | 11 | 12 | 14 | 16 |

During operation, stir the crude oil evenly, and heat it to 70~75℃ with dilute brine or phosphoric acid (concentration 90%)

c. Washing

For the palm oil refining,After the soapstock is released, the oil is further heated to 90°C, and then hot water is added for washing and stirring. The water temperature should be about 5~10℃ higher than the oil temperature, and the water temperature is too low to easily emulsify. After the water is added, continue to stir for 5 minutes, then let it settle for 2-4 hours, release the soapy water, and wash it repeatedly for 2 to 3 times, depending on the quality of the clear oil.

d. Decolorization operation method:

For the palm oil refining,Turn on the vacuum pump, vacuum degree ≥700mmHg

First, suck the washed alkali refining oil into the decolorizing pot, stir and heat up the oil to increase the oil temperature to 105°C-110°C, and carry out vacuum drying and dehydration for 30-40 minutes to reduce the moisture content to below 0.1%.Then inhale a small amount of decolorizing agent

e. Deodorization operation method

For the palm oil refining,The decolorizing oil is sucked into the deodorizing pot by a vacuum pump for deodorization. Its purpose is to remove some odorous substances in the oil, such as residual solvents, low molecular weight aldehydes, ketones, acids, soap odors, clay odors, fishy odors, etc. The process of deodorization is essentially a process of steam distillation, which removes odorous substances through hot water vapor under high temperature (240°C-260°C) and vacuum conditions. When the vacuum degree reaches 755mmHg or more, start distillation and deodorization timing.

Deodorization time: 4 hours;

Deodorization temperature: 240℃/755mmHg~260℃/759mmHg;

Deodorization vacuum degree: above 755mmHg;

The entire timing process must be steam distilled;

After the deodorization is completed, continue to close the direct steam under vacuum, close the conduction oil, and open the cooling water valve. When the oil temperature drops to about 60-80℃, close the vacuum pump valve. After the sampling inspection is qualified, the refined oil production process is completed.