Peanut Oil Refining

The purpose of peanut oil refining is to remove impurities in crude peanut oil to obtain peanut oil that meets national standards. Does that need to be refined for peanut oil? What peanut oil refining equipment is needed? The engineers of victoryoilmachinery will analyze for everyone based on the national standard of peanut oil and the experience of doing peanut oil production projects.

The peanut oil produced by the pressing method has already met the national first-class peanut oil standard and does not need to be refined. If you want to obtain high-quality peanut oil and increase the value of peanut oil, you only need to freeze and filter the peanut oil.

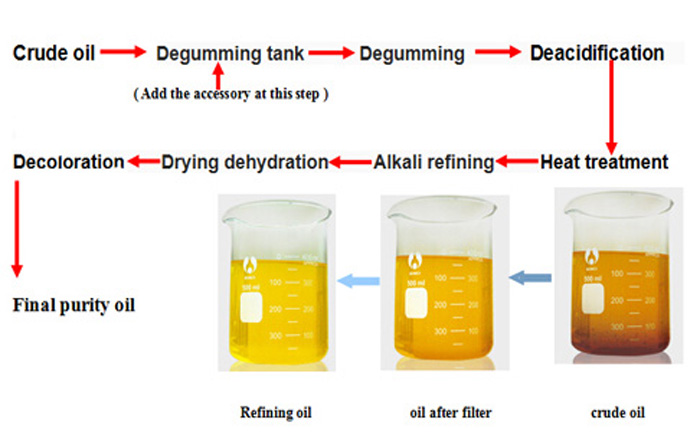

The peanut oil produced by the leaching method needs to be refined. The leached peanut oil contains various impurities, such as peptic impurities, free fatty acids, pigments and odor substances, which need to be removed by peanut oil refining equipment to obtain peanut oil that meets national standards. (Related reading: Edible oil refining process)

There are three main types of peanut oil refining equipment provided by victoryoilmachinery: peanut oil intermittent refining equipment, peanut oil semi-continuous refining equipment and peanut oil full continuous refining equipment. Different customers' needs and budgets require different peanut oil refining equipment.

Peanut oil intermittent refining equipment is suitable for small peanut oil manufacturers or peanut oil refiners. The applicable processing capacity is generally 1 ton/day, 2 tons/day, 3 tons/day, 5 tons/day, 10 tons/day and 20 tons/day . Peanut oil batch refining often uses chemical refining methods to process peanut oil. Chemical refining generally refers to the addition of lye in the deacidification process to neutralize the free fatty acid to remove the free fatty acid. Peanut oil intermittent refining equipment has a small footprint, low investment cost and high refining efficiency. It is the star product of Henan Guorui and a common choice for peanut oil manufacturers.

Peanut oil semi-continuous refining equipment is suitable for small and medium-sized peanut oil manufacturers or peanut oil refiners. The applicable processing capacity is generally 10 tons/day, 15 tons/day, 20 tons/day, 25 tons/day, 30 tons/day, 35 tons /Day, 40 tons/day, 45 tons/day, 50 tons/day. Peanut oil semi-continuous refining can use physical refining or a combination of physical and chemical refining to refine peanut oil. Physical refining generally refers to the process of using direct steam distillation to remove free fatty acids in a deodorizing tower. Part of the peanut oil semi-continuous refining equipment is intermittent refining and the other is full continuous refining. It combines the dual characteristics of batch refining and full continuous refining. The investment cost is lower than that of full continuous refining equipment. The refining operation process is more efficient than batch refining. High, can realize the different needs of customers.

Peanut oil full continuous refining equipment is suitable for large-scale peanut oil manufacturers or peanut oil refiners, and the applicable processing capacity is generally more than 30 tons/day. Peanut oil continuous refining generally uses physical refining to process peanut oil. It is characterized by continuous refining process, high refining efficiency, high quality of peanut oil after refining, and very little oil loss. It is more suitable for large-scale peanut oil refining factories.

Of course, the processing capacity is only a consideration when selecting the required peanut oil refining equipment. The customer's budget and the target market's index requirements for refined peanut oil can also affect the choice of refining equipment. For example, an Indonesian customer of victoryoilmachinery has a refining capacity of 5 tons per day, but he chose semi-continuous refining equipment. On the one hand, the customer’s target market has relatively high requirements for edible oil, and the other customer’s investment budget is also relatively high, so the engineer of victoryoilmachinery recommended and provided him with edible oil semi-continuous refining equipment. At present, the refining plant of the Indonesian customer is operating normally.