Combined deodorizating tower manual

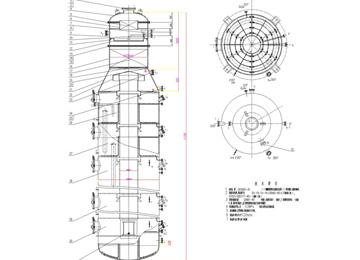

1. Description of the structure design of the combined deodorizating tower

The upper part of the combined deodorizating tower is a packing section, and the lower part is a plate section. The structured packing of the upper packing section is a thin stainless steel plate with a stamping or corrugated shape with a thickness of 0.2-0.5mm, uniformly distributed with small holes, which are cut into Put the proper size into the tower body, its advantages are large specific surface area (250m2/m3—750m2/m3), good dispersion of liquid and vapor on the surface of the packing, no channeling phenomenon, fast mass transfer, and pressure drop small. The lower plate section is divided into three layers, each with 6 grids and each grid has a heating device. The oil flows into the next layer through the overflow pipe, and finally is discharged through the oil outlet pipe at the bottom of the tower.

2. Features of combined deodorizating tower

1) Low steam consumption

Since most of the fatty acids and volatile odorous substances are removed in the packing section, the distillation load of the plate section is light, and the retention time of the oil in the plate section is greatly shortened, about 30 minutes.Therefore, the steam consumption of the combined deodorizating tower is very low, only equivalent to 30% of the ordinary tray tower, about 0.5%-1% of the oil weight.

2) The finished oil has good color

The decolorized oil stays in the plate section of the combined deodorizating tower. Some heat-sensitive pigments that cannot be removed by adsorption can be decomposed under high temperature vacuum to achieve the effect of thermal decolorization. The residence time is not long, and it is less likely to cause the increase in peroxide value and the production of new pigments than the ordinary plate tower. Therefore, the color of the product oil deodorized by the combined deodorizating tower is lighter than that of the ordinary packed tower and the plate tower.

3) Good deacidification effect and low refining consumption

The combined deodorizating tower uses the principle of physical deacidification. After the decolorized oil enters the packing section of the combined deodorizating tower, most of the fatty acids are quickly removed within 2-5 minutes,There is no need to carry out alkali refining in the pre-treatment process, which avoids the loss in the alkali refining link and reduces the refining consumption.and the benefits are particularly obvious when used in the processing of high acid value oils such as rice bran oil, tea seed oil, and industrial slop oil. The oil stays in the plate section for a short time, which can avoid the increase in the acid value of the deodorized oil due to the production of new free fatty acids.

3. Combined deodorizating tower system technology

The combined deodorizating tower is mainly used in continuous or semi-continuous refining production lines. The decolorized oil is pumped into the deaerator at a constant flow rate through a pump, and the oil is sprayed out through multiple nozzles on the feed pipe.The high vacuum degree of the absolute pressure of about 400pa is maintained in the degasser to release the small amount of air mixed in the oil.The oil comes out of the deaerator, is pumped into the oil-oil heat exchanger, exchanges heat with the hot oil from the deodorization tower, and is heated to at least 170-180°C. From the oil to oil heat exchanger, the oil flows into the heat transferring oil heater and is heated to 250-260°C. The heat transferring oil is heated to 290-310°C in the heat transferring oil boiler and is recycled throughout the process.The hot oil to be deodorized enters the combined deodorizating tower from the heat transferring oil heater. The fatty acid and other relatively volatile odor parts are removed by direct steaming in the packing section, and then enters the plate section for deodorization and thermal decolorization.The deacidified and deodorized oil is discharged from the combined deodorizating tower, pumped into the heat exchanger to exchange heat with the oil to be deodorized, then enters the cooler, is cooled by water, and the oil temperature after cooling is not higher than 70°C, finally passes through the fine filter , And then stored in the refined oil storage tank.

4. Technical characteristics of plate deodorizating tower

Production capacity: 30-60T/D, production method: semi-continuous.

The outer diameter of the tower body: 1500mm, the number of layers: 4.

The height of the tray: 1200mm.High tray liquid levelt: 700mm-900mm.

stripping time for each layer: 30min, 120min in total.

Deodorization temperature: 180-240℃, working pressure: 266.6-666.5Pa.

Direct steam consumption: 40-50kg/T oil, FFA content of refined oil: 0.1%.

Dimensions: diameter φ1700mm, height: about 10000mm.

About coal consumption for processing 1T oil: 135kg, power consumption: 4KWh/T oil.

5. Technical characteristics of combined deodorizating tower

Production capacity: 35-45T/D, production method: continuous,

the outer diameter of the upper section is φ450mm, and the diameter of the lower plate section is φ1400mm.

The height of the upper packing layer: 7500mm, the height of the lower plate layer: 3000mm, three layers.

Deodorization temperature: 250-260℃, working pressure: about 400Pa.

Direct steam consumption: 23-27kg/T oil, FFA content of refined oil: 0.03%.

Deodorization time: 2-5min for packing section, 30min for plate section.

About coal consumption for processing 1T of oil: 47kg, power consumption: 3KWh/T of oil.

Hot tags: Oil refining, Full continuous physical refining, Deacidification and deodorization equipment, Acid value reduction equipment,Fatty acid removal equipment,Deodorizating tower,