Professional Sunflower Seed Hulling Machine,Nuts Hulling Machine

- Henan Victor Machinery Equipment Co.,Ltd

- Made In China

- Other supporting equipment-91

This sunflower seed hulling machine is composed of cleaning and multi-stage separation, and can be designed into different screens, which can handle: pumpkin seeds, pine seeds, melon seeds,Buckwheat Hulling,oats Hulling,yuanbao maple, flax seeds, rape

Professional Sunflower Seed Hulling Machine,Nuts Hulling Machine details

Professional Sunflower Seed Hulling Machine,Nuts Hulling Machine

1.Product Description

| KTF4-3000 Sunflower seed hulling & separating machine | ||

| Perfect kernel rate>96% | The ratio of seed & kernel in shell ≤0.3% | Equipment weight:5100kg |

| Screen surface width:1.66m | Sheler:4 sets |

Sunflower seed capacity:1000-1200kg/h Sunflower yield: 800kg~1000kg/h Oleaginouseed capacity:1200-1500kg/h Oleaginous seed yeild: 1000kg~1200kg/h |

| Equipment power:32.2kw | Machine dimension (L * W * H /m):7*3.3*5.5m | Broken kernels rate≤ 4% |

| The cleanliness level in shelling :80% | The ratio of shell in kernel:2% | The ratio of kernel in shell:2.5% |

| Power consumption per ton per hour(kw.h/t) :32.2 | Noise figure /dB(A) : 80 | The dust concentration(mg/m3): 10 |

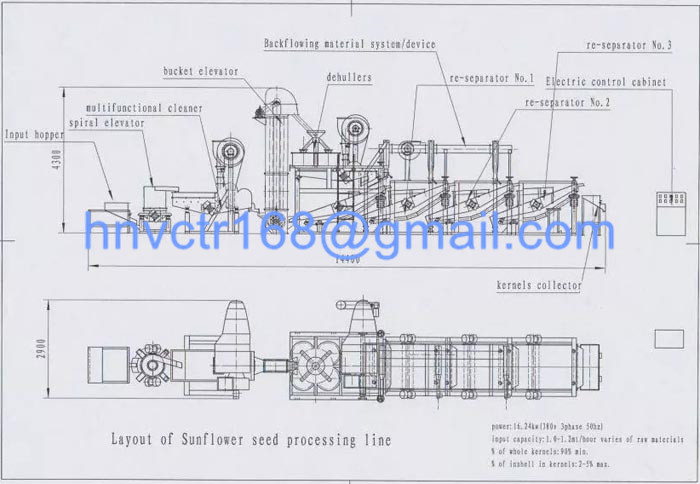

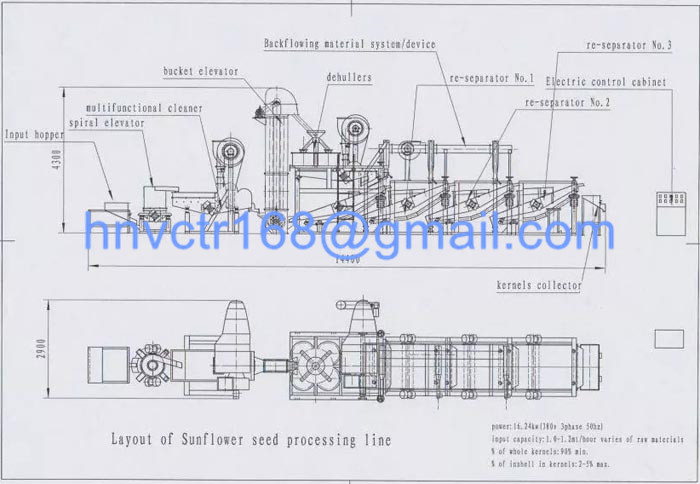

2. Working Mechanism

Materials are carried by fan blower-driven elevator and go through dust-removing and destoner machine. Then, they are dropped into rollers to break the shell. The hulled materials enter Floating Peels and Kernels Separator for separating. The separated peels are collected and conveyed out by an spiraling sheave device for packaging. The semi-finished products go through primary screening and secondary screening. The unshelled materials will be returned to the secondary screening by fan blower-driven hoist, and through secondary screening, they are lifted by anti-broken elevator and dropped to rollers for secondary hulling. The separated products are delivered to Refining Screener I, Broken Kernels Screener and then Refining Screener II, after that, the final products are transported to Storage Bin

3. Product Features:

It guarantees the perfect kernel rate requirement in utmost scale, and satisfies the demand for shelling the waste materials from gravity grader, screening machine and worm-damaged materials

4. More detailed features

1). Anti-broken hoisting system: It guarantees the perfect kernel rate requirement in utmost scale,

2). Roller block: A kind of special ceramic block is adopted, which is enduring, wearing-resisting, long-live and easy to replace

3).Fan blower-driven hoist for accessory materials adopts obstructing plate structure with rubber and steel, which prevents materials from accidentally entering the hoist and reduces the broken rate of materials

4).Fan blower-driven hoist unloading gate: a hopper shape design is adopted, the hinge plate is closed by air sucking when there is no material, which dose not affect hoisting. At the time materials have been accumulated to certain weight, the unloading gate is open to unload materials, after dumping from the hopper, the gate will be automatically closed again at the effect of air-sucking

5).The unloading gate for Floating Peels and Kernels Separator: An adjustable design is adopted, which can function to evenly spread materials. It can also adjust the peel extracting quantity according to different materials to achieve best peel separating results.

6).Fish-Scale Sieve: the staggered distribution structure ensures separating materials at any place of the sieve

7).Sheller Heat Radiator:there are four hive-shaped radiators outside shellers to provide good working condition for motors and ensures their life span

8).Adjustable Screw: to adjust the angle of screening sieve and refine screening sieve to reach best separating results

9).Broken kernel Sieve: zinc coating steel wire is adopted for the sieve, which is water-proof and enduring

Materials are carried by fan blower-driven elevator and go through dust-removing and destoner machine. Then, they are dropped into rollers to break the shell. The hulled materials enter Floating Peels and Kernels Separator for separating. The separated peels are collected and conveyed out by an spiraling sheave device for packaging. The semi-finished products go through primary screening and secondary screening. The unshelled materials will be returned to the secondary screening by fan blower-driven hoist, and through secondary screening, they are lifted by anti-broken elevator and dropped to rollers for secondary hulling. The separated products are delivered to Refining Screener I, Broken Kernels Screener and then Refining Screener II, after that, the final products are transported to Storage Bin

3. Product Features:

It guarantees the perfect kernel rate requirement in utmost scale, and satisfies the demand for shelling the waste materials from gravity grader, screening machine and worm-damaged materials

4. More detailed features

1). Anti-broken hoisting system: It guarantees the perfect kernel rate requirement in utmost scale,

2). Roller block: A kind of special ceramic block is adopted, which is enduring, wearing-resisting, long-live and easy to replace

3).Fan blower-driven hoist for accessory materials adopts obstructing plate structure with rubber and steel, which prevents materials from accidentally entering the hoist and reduces the broken rate of materials

4).Fan blower-driven hoist unloading gate: a hopper shape design is adopted, the hinge plate is closed by air sucking when there is no material, which dose not affect hoisting. At the time materials have been accumulated to certain weight, the unloading gate is open to unload materials, after dumping from the hopper, the gate will be automatically closed again at the effect of air-sucking

5).The unloading gate for Floating Peels and Kernels Separator: An adjustable design is adopted, which can function to evenly spread materials. It can also adjust the peel extracting quantity according to different materials to achieve best peel separating results.

6).Fish-Scale Sieve: the staggered distribution structure ensures separating materials at any place of the sieve

7).Sheller Heat Radiator:there are four hive-shaped radiators outside shellers to provide good working condition for motors and ensures their life span

8).Adjustable Screw: to adjust the angle of screening sieve and refine screening sieve to reach best separating results

9).Broken kernel Sieve: zinc coating steel wire is adopted for the sieve, which is water-proof and enduring

tag : pumpkin seeds Hulling,pine seeds Hulling,nuts Hulling

Professional Sunflower Seed Hulling Machine,Nuts Hulling Machine,This sunflower seed hulling machine is composed of cleaning and multi-stage separation, and can be designed into different screens, which can handle: pumpkin seeds, pine seeds, melon seeds,Buckwheat Hulling,oats Hulling,yuanbao maple, flax seeds, rape