Solvent Extraction of seed cake

- Henan Victor Machinery Equipment Co.,Ltd

- Made In China

- Oil solvent extraction equipment-33

High-quality solvent extraction device, which is mainly composed of extraction desolventizer, evaporator, DTDC decontamination machine, stripper and condenser, low solvent consumption, high degree of automation, processing capacity 20-1000TPD

Solvent Extraction of seed cake details

1. Use range cooking oil rotocel extractor machine

2. Professional advice

3. Solvent extraction plant price Main products

1. Solvent pumps

2. Roary extractor

3. DTDC

4. Miscella tank 1st

5. Miscella tank 2nd

6. Miscella stripping

7. condensers

4. Echnological process introduction

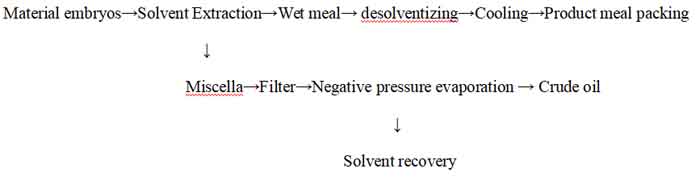

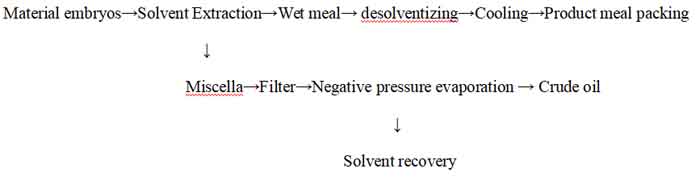

4.1 Solvent extraction process

4.2 Wet meal desolventizing process

4.3 Negative pressure evaporation process

4.4 Solvent condensation & recovery process

4.5 Paraffin oil recovery process

4.6 Automatic control system

Solvent extraction fits for pre-press extraction of high-oil-content materials and direct once time extraction of low-oil content materials. Our machine is suitable to various raw materical,such as sunflower seed cake,tea seed cake, groundnut cake, cottonseed cake, palm cake, rice bran cake, soybean cake, corn and palm cake,rapeseed cake, etc.

2. Professional advice

Please kindly inform us your required daily capacity, treated quantity, raw material, covering space and related data,so that we can make flow chart production line for you as your requirement. we will stand at your point to suggest low cost and suitable production line for you. Sincerely want to cooperate with you.

3. Solvent extraction plant price Main products

1. Solvent pumps

2. Roary extractor

3. DTDC

4. Miscella tank 1st

5. Miscella tank 2nd

6. Miscella stripping

7. condensers

4. Echnological process introduction

4.1 Solvent extraction process

The material is divided into several independent units on the material bed, which can effectively prevent miscella at all levels from fleeing hither and thither on the material layer and ensure the concentration gradient between several sprays.

Immersion area appears in each lattice, which can help achieve better immersion effect.

The chain box is supported by track and can prolong the service life of screen deck by not touching it.

The Drag chain extractor is driven by world leading double-shaft hydraulic motor, with balance force, reliable operation and less maintenance cost.

Specialty suitable for the extraction of high oil and high power materials, and better immersion effect can be expected for ordinary oil plants.

Immersion area appears in each lattice, which can help achieve better immersion effect.

The chain box is supported by track and can prolong the service life of screen deck by not touching it.

The Drag chain extractor is driven by world leading double-shaft hydraulic motor, with balance force, reliable operation and less maintenance cost.

Specialty suitable for the extraction of high oil and high power materials, and better immersion effect can be expected for ordinary oil plants.

4.2 Wet meal desolventizing process

Passivate and damage the anti-nutritional components such as the urea enzyme and trypsin in the meal, and improve meal value in use.

Control the protein denaturation degree in the meal , and improve the NSI index effectively.

It can better regulate the color, flavor and taste of the meal.

It can better reduce residual solvent in the meal and regulate the meal moisture, so as to guarantee the minimum solvent consumption and safe use of the meal.

Control the protein denaturation degree in the meal , and improve the NSI index effectively.

It can better regulate the color, flavor and taste of the meal.

It can better reduce residual solvent in the meal and regulate the meal moisture, so as to guarantee the minimum solvent consumption and safe use of the meal.

4.3 Negative pressure evaporation process

The liquid from the extractor is the miscella containing grease and oil, which can be separated out according their different vaporization temperatures. Our company mainly uses vacuum evaporation technology, and it can reduce solvent leakage and consumption. The separated solvent vapour is cooled and recycled back to the extractor for reuse, which can improve the solvent efficiency.

4.4 Solvent condensation & recovery process

Solvent condensation system combines with evaporation system closely, and evaporative condenser and steam stripping condenser all work under negative pressure. Non-condensable gas enters the energy saver from the shell of the first evaporator. In energy saver, non-condensable gas exchanges heat with condensate from the evaporative condenser. Finally, the condensate temperature discharged from energy saver is increased, and the solvent separated from water goes to solvent holding tank. The high temperature makes it unnecessary to be reheated for the recycling, so as to save energy.

Non-condensable gas from energy saver enters desolventizing condenser, in which a great deal of gas is condensed, and the tail gas is discharged into the final condenser. The solvent gas from the extractor enters extraction condenser, and the non-condensable tail gas enters the final condenser. For the free gas in final condenser, diversion box, holding tank, underground solvent library and miscella tank, cool them with low-temperatured cold water to recycle most of solvent gas. The tail gas with little solvent goes to paraffin recovery process.

Non-condensable gas from energy saver enters desolventizing condenser, in which a great deal of gas is condensed, and the tail gas is discharged into the final condenser. The solvent gas from the extractor enters extraction condenser, and the non-condensable tail gas enters the final condenser. For the free gas in final condenser, diversion box, holding tank, underground solvent library and miscella tank, cool them with low-temperatured cold water to recycle most of solvent gas. The tail gas with little solvent goes to paraffin recovery process.

4.5 Paraffin oil recovery process

Tail gas first enters paraffin absorption tower, and then comes the counter-current absorption of paraffin and tail gas, which can reach the ideal state when the stainless steel packing has large surface area. The solvent content in discharged liquid paraffin (called rich oil) is not more than 5%, so as to ensure the maximum absorption rate

4.6 Automatic control system

Our company has applied the automatic control system with advancedness, security, reliability into the pretreatment, extraction, refining and fractionation in large oil plants.

tag : high degree of automation,low solvent consumption

Solvent Extraction of seed cake,High-quality solvent extraction device, which is mainly composed of extraction desolventizer, evaporator, DTDC decontamination machine, stripper and condenser, low solvent consumption, high degree of automation, processing capacity 20-1000TPD