Cost-effective peanut oil processing equipment, the best quality peanut oil equipment in China

- Henan Victor Machinery Equipment Co.,Ltd

- Made In China

- Oil Production line-75

The production of peanut oil can be directly squeezed, or pre-squeezed and leached, and then refined, and finally qualified edible oil is obtained. Our company can initially design and quote in detail according to customer needs

Cost-effective peanut oil processing equipment, the best quality peanut oil equipment in China details

Peanut oil processing equipment, peanut oil refining equipment

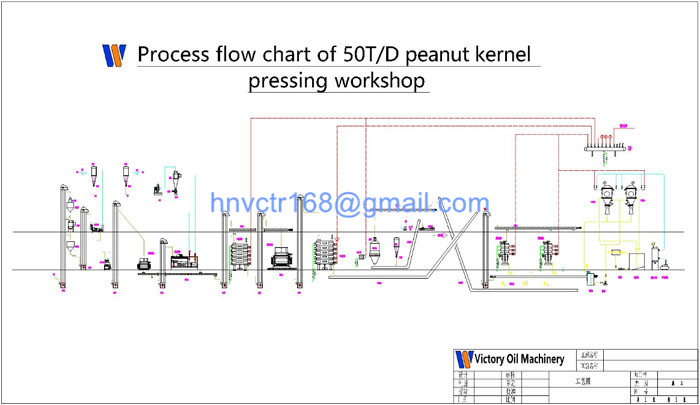

1. Peanut pressing process

2. Description of peanut pressing process

1) Clean up

The raw materials pass through a vibrating cleaning screen to remove large and small impurities in the raw materials; then enter the specific gravity stone remover to remove the side-by-side mud and side-by-side stones in the material; the dust and light impurities in the material are removed by the fan and the dust removal air net; there are iron impurities in the material It will affect the life of mechanical equipment. There is a magnetic separator in the process to remove iron impurities in the material.

2) Broken

The purpose of crushing is to make the oil have a certain particle size, and the surface area increases after crushing, which is conducive to the transfer of temperature and moisture during steaming, and is more conducive to the subsequent oil production. After the oil is broken, the particle size should be uniform, no oil, no agglomeration, less powder, and the particle size meets the requirements.

3) Steam and stir fry

Steaming and frying is to adjust the moisture and temperature of the oil to meet the requirements of high temperature and low moisture in the raw material. The steamed rapeseeds are sent to the pressing process through the conveying equipment.

4) Press

After the pretreatment of the material before pressing is completed, it can enter the oil press for pressing.

The number of configurations is 4-10, and the benefits of a few more oil presses: the output adjustment is flexible, and the rest of the equipment can continue to work when one is maintained, and the impact on the production capacity is also small.

5) Filter

The squeezed crude oil is filtered to remove the particulate impurities in the grease, and the filtered oil is clear and bright with good color.

3. Process technology characteristics

The design of the dust removal system is reasonable, and the discharged gas meets the national environmental protection requirements; the degree of automation is high, and 1-2 workers can complete the operation of the entire production equipment. Multiple one-time squeezing screw oil presses have low residual oil and flexible output, which reduces the impact on production capacity during equipment maintenance.

4. Peanut oil refining workshop

5. Peanut oil refining process

1) Process flow chart

Filter crude oil → degumming, deacidification, water washing → drying, decolorization → decolorization oil filtration → continuous deodorization → precision filter → refined oil tank

2) Features of process equipment

The whole line is mainly based on heat exchange, which improves the efficiency of heat use, saves energy and saves steam; the exhaust steam used by the trap is used to enter the hot water tank;

Acid and alkali automatic metering and adding system; decolorization filter adopts automatic control execution unit, according to the program setting to complete the cycle, filter, purging, unloading, switching and other operations;

The use of partial packing combined deodorization tower, the packing structure reduces the high temperature residence time of deodorized oil, reduces the generation of trans fatty acids, and reduces steam consumption;

The pipelines and equipment in contact with the oil in the deodorization section are made of stainless steel; the oil quality, production consumption, equipment configuration, and system control have reached the current domestic first-class level.

6. Process description of peanut refining workshop

1) Degumming and washing section

The free fatty acids contained in peanut crude oil are not conducive to the storage and use of oils, and must be neutralized with alkali and then removed. Therefore, deacidification is also called alkali refining. Soap feet can also absorb impurities and pigments remaining during hydration and degumming. After sufficient alkali refining, the content of free fatty acids can be reduced to 0.01%-0.03%, and phospholipids are about 0.0015%. Function: Remove the harmful acid value in the oil, remove some pigments and impurities.

2) Decolorization section

Function: Remove the pigment in the oil and use the oil color to meet the national standard. Remove the water in the oil and increase the shelf life of the oil. The temperature is self-controllable and adjustable during the entire decolorization process. The filter system realizes automatic oil intake, circulation, filtration, cooking cakes, slag discharge and other operations

3) Deodorization section

The decolorized oil from the decolorization section will enter the deodorization section to remove free fatty acids, aldehydes, ketones, hydrocarbons and other small molecules that cause odor. A deodorization tower is used to remove these substances with steam under high vacuum conditions. The removed fatty acids are collected in the fatty acid trap and sent to the receiving tank as a by-product. The deodorizing temperature is about 225℃-245℃.

The number of configurations is 4-10, and the benefits of a few more oil presses: the output adjustment is flexible, and the rest of the equipment can continue to work when one is maintained, and the impact on the production capacity is also small.

5) Filter

The squeezed crude oil is filtered to remove the particulate impurities in the grease, and the filtered oil is clear and bright with good color.

3. Process technology characteristics

The design of the dust removal system is reasonable, and the discharged gas meets the national environmental protection requirements; the degree of automation is high, and 1-2 workers can complete the operation of the entire production equipment. Multiple one-time squeezing screw oil presses have low residual oil and flexible output, which reduces the impact on production capacity during equipment maintenance.

4. Peanut oil refining workshop

5. Peanut oil refining process

1) Process flow chart

Filter crude oil → degumming, deacidification, water washing → drying, decolorization → decolorization oil filtration → continuous deodorization → precision filter → refined oil tank

2) Features of process equipment

The whole line is mainly based on heat exchange, which improves the efficiency of heat use, saves energy and saves steam; the exhaust steam used by the trap is used to enter the hot water tank;

Acid and alkali automatic metering and adding system; decolorization filter adopts automatic control execution unit, according to the program setting to complete the cycle, filter, purging, unloading, switching and other operations;

The use of partial packing combined deodorization tower, the packing structure reduces the high temperature residence time of deodorized oil, reduces the generation of trans fatty acids, and reduces steam consumption;

The pipelines and equipment in contact with the oil in the deodorization section are made of stainless steel; the oil quality, production consumption, equipment configuration, and system control have reached the current domestic first-class level.

6. Process description of peanut refining workshop

1) Degumming and washing section

The free fatty acids contained in peanut crude oil are not conducive to the storage and use of oils, and must be neutralized with alkali and then removed. Therefore, deacidification is also called alkali refining. Soap feet can also absorb impurities and pigments remaining during hydration and degumming. After sufficient alkali refining, the content of free fatty acids can be reduced to 0.01%-0.03%, and phospholipids are about 0.0015%. Function: Remove the harmful acid value in the oil, remove some pigments and impurities.

2) Decolorization section

Function: Remove the pigment in the oil and use the oil color to meet the national standard. Remove the water in the oil and increase the shelf life of the oil. The temperature is self-controllable and adjustable during the entire decolorization process. The filter system realizes automatic oil intake, circulation, filtration, cooking cakes, slag discharge and other operations

3) Deodorization section

The decolorized oil from the decolorization section will enter the deodorization section to remove free fatty acids, aldehydes, ketones, hydrocarbons and other small molecules that cause odor. A deodorization tower is used to remove these substances with steam under high vacuum conditions. The removed fatty acids are collected in the fatty acid trap and sent to the receiving tank as a by-product. The deodorizing temperature is about 225℃-245℃.

tag : Peanut Oil Press,Peanut Oil Refinery

Cost-effective peanut oil processing equipment, the best quality peanut oil equipment in China,The production of peanut oil can be directly squeezed, or pre-squeezed and leached, and then refined, and finally qualified edible oil is obtained. Our company can initially design and quote in detail according to customer needs