Good price cottonseed pre-pressing description

- Henan Victor Machinery Equipment Co.,Ltd

- Made In China

- Oil Production line-68

Our company uses the most advanced cottonseed oil processing technology and technology. We have our own unique patents. It has a high degree of automation and low failure rate. Cottonseed oil can be refined and defatted to reach the first grade oil. C

Good price cottonseed pre-pressing description details

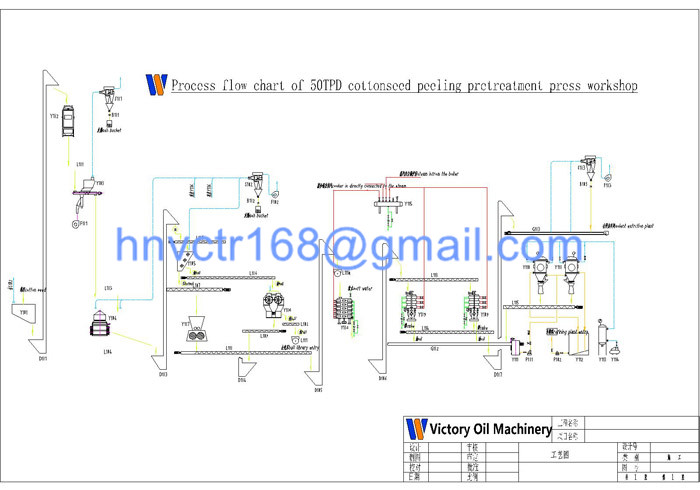

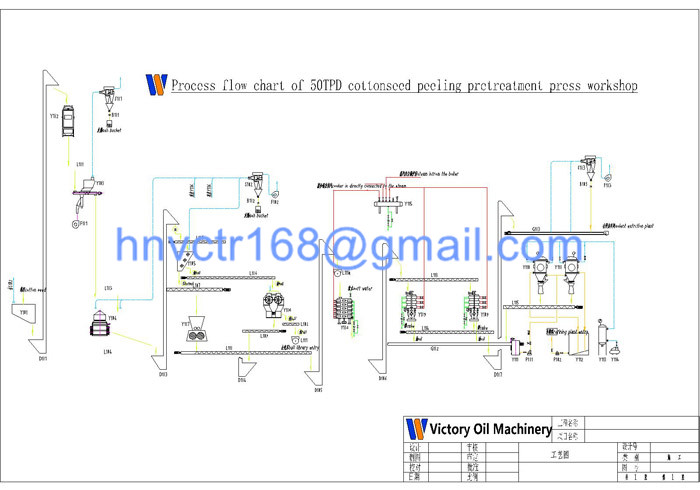

50-100TPD cottonseed pre-pressing process description

1. Process equipment: (see equipment list for details)

2. Process technical characteristics:

(1) Continuous and automated operation of workshop production;

(2) The equipment used is stable, low noise, and good performance;

(3) The equipment used is working in a closed state, so the workshop environment is good and the safety factor is high;

(4) Taking into account the environmental protection requirements of modern industry, the workshop is also equipped with a powerful dust removal system to meet the requirements of production and environmental protection;

(5) Crude oil passes through the slag scraper and the oil tank for secondary slag removal, with less slag, which can reduce the loss of grease in oil refining and improve the refining rate.

3. Process description:

Before the oil is leached, different mechanical treatments, heat treatments and tempering treatments are required. The pretreatment of cottonseed includes cleaning, peeling, separation of kernel and shell, embossing, steaming, pre-pressing, and crude oil filtering. The process flow is:

Cottonseed → metering → winnowing → peeling → shell and kernel separation → softening → embossing → steaming and frying → squeezing oil → cake to the leaching workshop, crude oil to the refining workshop after coarse filtration

4. The specific description is as follows:

(1) Cleaning process: In order to effectively achieve the cleaning effect, ensure a good operating environment and production stability, and at the same time improve the quality of the finished product, the process is equipped with a high-efficiency wind separator to clean up large and small impurities and remove side-by-side stones and side-by-side mud; configuration Unpowered magnetic separator removes iron impurities; equipped with dust removal air net to ensure environmental sanitation.

(2) Shelling and kernel shell separation process: In order to ensure the shelling effect, a disc shelling machine is equipped in the process. This machine can adapt to cottonseed raw materials with different moisture. The kernel shell separation adopts a double-cylinder circular sieve. The equipment has a large processing capacity, which can fully ensure that the kernel rate in the shell and the shell content in the kernel do not exceed the corresponding indicators.

(3) Softening process: It is to soften the material to meet the requirements of the water and temperature of the squeezing and leaching material in the rear pre-pressing and leaching. At the same time, it is also conducive to not sticking to the roll when rolling the embryo, which is easy to make the embryo be pressed To form uniform flakes, to create favorable conditions for reducing the residual oil of the meal, the suitable moisture content of the embryo after softening and dewatering is 10-11%.

(4) Billet rolling process: In order to destroy the cell wall of the embryo, the granular shape is rolled into flakes, the surface area is increased, the thickness is reduced, and the external structure of the blank is changed. It is good for heating and also good for absorbing water when wetting. The water volatilizes during steaming and frying, creating favorable conditions for the subsequent process. In order to prevent the powder degree of the embryo from increasing, the thickness of the rapeseed embryo should be controlled at 0.35mm

(5) Steaming and frying process: Steaming and frying is the process of adding water (wetting), steaming (steaming the billets), and drying (frying billets) to the crushed or rolled billets to become cooked billets. During steaming and frying, due to the effect of moisture and temperature, the protein in the embryo is fully denatured, so that the material reaches the plasticity and elasticity suitable for the pressure of the oil press, and establishes a suitable press chamber pressure, thereby increasing the oil output rate of the oil press , And get the ideal pre-pressed cake and high-quality fat. This process uses YZCL210*5 vertical steaming and frying pan, steaming moisture requirement: 12-14%; steaming temperature: 105-1100C; steaming time: 60min.

(6) Squeezing process: The purpose is to pre-squeeze a part of the oil from high-oil oilseeds to create more favorable conditions for leaching. This process uses the currently mature 204-3 screw pre-press. Feeding water requirement: 3.5-4.2%; Feeding temperature: 105-1100C; Residual oil in cake is about 14%.

(7) Filtering of squeezed oil: The squeezed oil is first filtered with an oil-slag scraper. Compared with the traditional slag raking machine, the device has the advantages of smooth transmission, low failure rate, high oil-slag separation efficiency, and reduced floor space. It is an ideal equipment for oil-slag separation. After passing through the oil-slag scraper, the squeezed oil enters the slag scraper for further separation, and the squeezed oil is pumped through the slag pump into the high-efficiency closed filter for filtration. The use of this filter can effectively reduce the labor intensity of workers, ensure the stability of production, high oil-slag separation efficiency (the impurity content in the oil is below 0.2%), and improve the oil refining rate and the quality of refined oil in the subsequent process . The separated oil residue is compressed by air, filtered by vibration, and then sent to the press through a screw conveyor for back extraction.

5. Process technical indicators

Average consumption index of 50TPD cottonseed pre-pressing process (calculated according to the feed amount per ton)

Power consumption: less than 50KWH/ton material

Steam consumption: less than 280Kg/ton material

Residual oil in cake: below 14%

Steaming temperature: 105

Water content in cake: less than 6%

Impurities in oil: less than 0.1%

1. Process equipment: (see equipment list for details)

2. Process technical characteristics:

(1) Continuous and automated operation of workshop production;

(2) The equipment used is stable, low noise, and good performance;

(3) The equipment used is working in a closed state, so the workshop environment is good and the safety factor is high;

(4) Taking into account the environmental protection requirements of modern industry, the workshop is also equipped with a powerful dust removal system to meet the requirements of production and environmental protection;

(5) Crude oil passes through the slag scraper and the oil tank for secondary slag removal, with less slag, which can reduce the loss of grease in oil refining and improve the refining rate.

3. Process description:

Before the oil is leached, different mechanical treatments, heat treatments and tempering treatments are required. The pretreatment of cottonseed includes cleaning, peeling, separation of kernel and shell, embossing, steaming, pre-pressing, and crude oil filtering. The process flow is:

Cottonseed → metering → winnowing → peeling → shell and kernel separation → softening → embossing → steaming and frying → squeezing oil → cake to the leaching workshop, crude oil to the refining workshop after coarse filtration

4. The specific description is as follows:

(1) Cleaning process: In order to effectively achieve the cleaning effect, ensure a good operating environment and production stability, and at the same time improve the quality of the finished product, the process is equipped with a high-efficiency wind separator to clean up large and small impurities and remove side-by-side stones and side-by-side mud; configuration Unpowered magnetic separator removes iron impurities; equipped with dust removal air net to ensure environmental sanitation.

(2) Shelling and kernel shell separation process: In order to ensure the shelling effect, a disc shelling machine is equipped in the process. This machine can adapt to cottonseed raw materials with different moisture. The kernel shell separation adopts a double-cylinder circular sieve. The equipment has a large processing capacity, which can fully ensure that the kernel rate in the shell and the shell content in the kernel do not exceed the corresponding indicators.

(3) Softening process: It is to soften the material to meet the requirements of the water and temperature of the squeezing and leaching material in the rear pre-pressing and leaching. At the same time, it is also conducive to not sticking to the roll when rolling the embryo, which is easy to make the embryo be pressed To form uniform flakes, to create favorable conditions for reducing the residual oil of the meal, the suitable moisture content of the embryo after softening and dewatering is 10-11%.

(4) Billet rolling process: In order to destroy the cell wall of the embryo, the granular shape is rolled into flakes, the surface area is increased, the thickness is reduced, and the external structure of the blank is changed. It is good for heating and also good for absorbing water when wetting. The water volatilizes during steaming and frying, creating favorable conditions for the subsequent process. In order to prevent the powder degree of the embryo from increasing, the thickness of the rapeseed embryo should be controlled at 0.35mm

(5) Steaming and frying process: Steaming and frying is the process of adding water (wetting), steaming (steaming the billets), and drying (frying billets) to the crushed or rolled billets to become cooked billets. During steaming and frying, due to the effect of moisture and temperature, the protein in the embryo is fully denatured, so that the material reaches the plasticity and elasticity suitable for the pressure of the oil press, and establishes a suitable press chamber pressure, thereby increasing the oil output rate of the oil press , And get the ideal pre-pressed cake and high-quality fat. This process uses YZCL210*5 vertical steaming and frying pan, steaming moisture requirement: 12-14%; steaming temperature: 105-1100C; steaming time: 60min.

(6) Squeezing process: The purpose is to pre-squeeze a part of the oil from high-oil oilseeds to create more favorable conditions for leaching. This process uses the currently mature 204-3 screw pre-press. Feeding water requirement: 3.5-4.2%; Feeding temperature: 105-1100C; Residual oil in cake is about 14%.

(7) Filtering of squeezed oil: The squeezed oil is first filtered with an oil-slag scraper. Compared with the traditional slag raking machine, the device has the advantages of smooth transmission, low failure rate, high oil-slag separation efficiency, and reduced floor space. It is an ideal equipment for oil-slag separation. After passing through the oil-slag scraper, the squeezed oil enters the slag scraper for further separation, and the squeezed oil is pumped through the slag pump into the high-efficiency closed filter for filtration. The use of this filter can effectively reduce the labor intensity of workers, ensure the stability of production, high oil-slag separation efficiency (the impurity content in the oil is below 0.2%), and improve the oil refining rate and the quality of refined oil in the subsequent process . The separated oil residue is compressed by air, filtered by vibration, and then sent to the press through a screw conveyor for back extraction.

5. Process technical indicators

Average consumption index of 50TPD cottonseed pre-pressing process (calculated according to the feed amount per ton)

Power consumption: less than 50KWH/ton material

Steam consumption: less than 280Kg/ton material

Residual oil in cake: below 14%

Steaming temperature: 105

Water content in cake: less than 6%

Impurities in oil: less than 0.1%

tag : cottonseed oil machine,Cottonseed Oil Equipment

Good price cottonseed pre-pressing description,Our company uses the most advanced cottonseed oil processing technology and technology. We have our own unique patents. It has a high degree of automation and low failure rate. Cottonseed oil can be refined and defatted to reach the first grade oil. C