20TPH Palm fruit pressing equipment production line

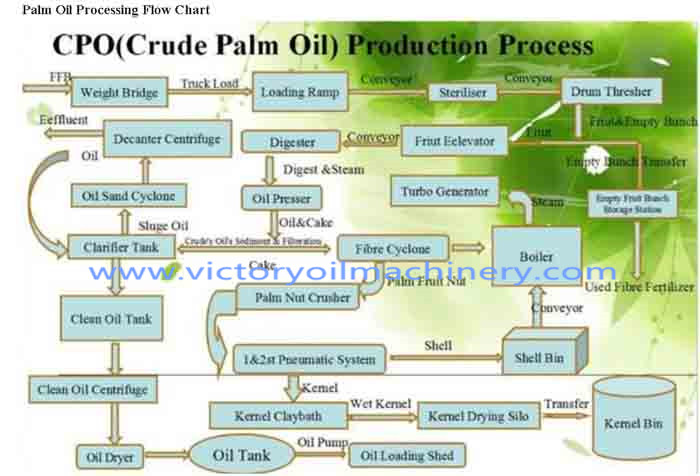

1. Palm oil Processing Chart

We have enough experience and advanced machinery for making palm oil, which lead the technicity in this field.

The rude oil from oil press or solvent process, which should be refined for better edible oil.

The capacity is from 5t to 500t per day.

1. Raw materials storage section

2. Sterilizing section

The purpose to prevent enzymes broken down.

3. Threshing section

The purpose of threshing is the oil palm fruit be separated from the fruit bunch through strong vibration.

4. Pressing section: Oil palm fruit first carry out cooking before pressed, fruit sterilized must be re-heating for the soft pulp, and damage pulp cell structure. Then enter into continuous screw press for pressing.

5. Clarification section: Machine-pressed crude oil first diluted with water washing, through settlement and filtration, the fiber material removed from the oil, and then carry out continuous settlement, the whole divided into two parts: Oil and sediment. Oil by centrifugal separation and through vacuum drying pumped into the storage tank for storing; Oil sediment by filtration and dirt oil separation, oil process second settlement, dirt oil mixture process clarification separation, Skim oil then carry out a second settlement, sewage pumps to sewage treatment pond for dealing with.

6. Finished oil storage and transportation section: Finished crude oil is stored in storage tanks.

7. Fiber separation section: Press cake broken by breaking screw conveyor and then transported into the fiber separation air net and fiber polishing roller for fiber separating.

8. Kernel recovery section: The stone processes intenerate tempering before broken, the intenerating stone by the corrugated crusher be divided into two or more petal, kernel was released.

9. Sewage treatment section

The by-products from the oil press are cake and soap residue. The cake could be used as animal food with our pelleting machinery, or source material for the other way of extraction. Soap residue is the source material for laundry soap with soap making machinery and washing detergent.

2. Our case