New technology of rice bran oil processing from China

- Henan Victor Machinery Equipment Co.,Ltd

- Made In China

- Oil Production line-73

Our company adopts the latest international rice bran oil processing technology. We have dozens of successful rice bran oil processing cases at home and abroad, and the processing tonnage is 10-1000TPD.

New technology of rice bran oil processing from China details

New technology of rice bran oil processing from China

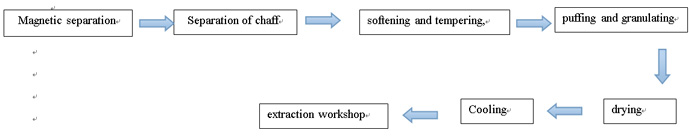

1.Rice bran pretreatment process

2. Process description

2.1 Magnetic separation cleaning

Magnetic separation cleaning is very important for the pretreatment process. Metal impurities may jam the equipment and cause serious damage to the equipment, shorten the service life of the equipment, and reduce the design efficiency. Use a magnetic separator to remove metal impurities, such as screws, nails, etc.

2.2 Separation of chaff

The separation of chaff is mainly achieved through screening and winnowing.

Because the rice bran is mixed with broken rice/rice glutinous rice, sometimes due to the damage of the rice sieve or poor assembly, the rice grains are mixed, if not separated, it will accelerate the abrasion of the extruder. More importantly, the broken rice contains more The starch in the puffing process can not form pressure. In addition, the starch in the broken rice is preheated and gelatinized, and it gradually agglomerates in the extractor, which is easy to "bridging".

The chaff separating sieve uses the centrifugal inertia force generated by the high-speed rotation of the heavy block to make the sieve body produce horizontal and vertical two-way vibration, so that the rice bran, broken rice/rice chaff is separated. It has the characteristics of large output and good separation effect.

2.3 Softening and tempering

The function of softening is to adjust the moisture and temperature of rice bran to make it plastic. Create favorable conditions for puffing. The softening temperature is generally 50 -80 ℃. At the same time, the softening time is generally about 20 minutes.

2.4. Puffing

After being softened and tempered, the rice bran enters the puffing machine for puffing treatment to strengthen the leaching effect and increase the output of the equipment. After the rice bran is subjected to a series of effects such as squeezing, kneading, shearing, pressure and other mechanical actions in the extruder, as well as a series of effects such as the moisture and heat effects of the injected steam, and frictional heat generation, the oil-containing cells of the oil are completely destroyed and the oil is fully exposed . At the end of the extrusion screw, the pressure and temperature of the material are very high. After the high temperature and high pressure material comes out of the hydraulic die, the pressure is suddenly relieved, the material expands rapidly, and the water evaporates quickly to obtain a loose, porous, and high-strength extruded material. .

2.5 Cool and dry

The expanded material enters the flap cooler for drying and cooling to improve the quality of the leaching material and improve the leaching effect

3. Extraction workshop

3.1 Process characteristics of leaching workshop

3.2 The leaching process is a large-scale production process, using a mature flat-rotation leaching device, DTDC steaming off machine

3.3 Meal foam system capture can effectively avoid the entrainment of the meal foam in the secondary steam entering the first long tube evaporator to ensure the heat transfer effect and evaporation efficiency;

3.4 The layout of the whole workshop is reasonable, generous and beautiful, convenient for operation and management.

3.5 The leaching is designed according to the flat-rotating leaching device, which achieves good contact between the solvent and the material and rapid draining. The embryo layer is completely extracted, which is very beneficial to reduce the oil content of the meal and the dissolution of the mixed meal. This extractor is designed with a material level controller The material level controller cooperates with the frequency modulation motor of the extractor to maintain a raw material bed with a certain material level. On the one hand, it can support the material and seal the extractor, and on the other hand, it can maintain the action of the frequency modulation motor of the overextractor. The material level of the extractor and the flow of wet meal sent to the desolventizer are balanced. In addition, this extractor has low power, stable action, low failure rate, no noise, low failure rate, and convenient maintenance. It is one of the advanced extractors.

3.6 The solvent gas enters the condenser, the condensate of all the condensers in the system is collected into the liquid pipeline, and flows into the solvent water separation combination box. The fresh solvent after the water separation can enter the extractor without heating or less heating.

3.7 The first steam and the second steam share a condenser, so that the lower solvent gas evaporated by the first steam and the higher solvent gas evaporated by the second steam will enter the condenser after being neutralized, which greatly reduces the load of the condenser and improves the condensation efficiency. The condensate is collected in the water distribution box, and the final non-condensable gas enters the tail gas condenser. After the one-step condenser, the non-condensable gas is fully absorbed and treated by the paraffin absorption system, and the exhaust gas is discharged.

3.8 After the condensed solvent enters the solvent tank, the waste water flows into the cooking tank and the steam injected by the negative pressure vacuum pump through the evaporation system is fully digested and discharged.

3.9 Wet meal enters the DT steaming machine from the inclined scraper conveyor with frequency modulation through the closed valve for desolvation drying and cooling treatment. The steaming machine used in this process digests and absorbs the advantages of the Crown Schumacher steaming machine and combines the domestic manufacturers to design a special desolventizing equipment. The material gate device is professionally designed, and the action is flexible and reliable. The desolubilization layer seals the special material to achieve the automatic control of the desolubilization house material level to ensure the constant desolubilization time and position of the wet meal.

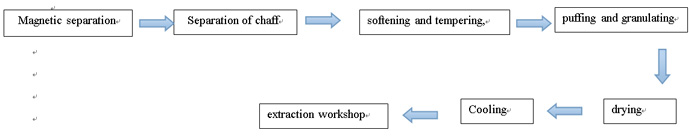

1.Rice bran pretreatment process

2. Process description

2.1 Magnetic separation cleaning

Magnetic separation cleaning is very important for the pretreatment process. Metal impurities may jam the equipment and cause serious damage to the equipment, shorten the service life of the equipment, and reduce the design efficiency. Use a magnetic separator to remove metal impurities, such as screws, nails, etc.

2.2 Separation of chaff

The separation of chaff is mainly achieved through screening and winnowing.

Because the rice bran is mixed with broken rice/rice glutinous rice, sometimes due to the damage of the rice sieve or poor assembly, the rice grains are mixed, if not separated, it will accelerate the abrasion of the extruder. More importantly, the broken rice contains more The starch in the puffing process can not form pressure. In addition, the starch in the broken rice is preheated and gelatinized, and it gradually agglomerates in the extractor, which is easy to "bridging".

The chaff separating sieve uses the centrifugal inertia force generated by the high-speed rotation of the heavy block to make the sieve body produce horizontal and vertical two-way vibration, so that the rice bran, broken rice/rice chaff is separated. It has the characteristics of large output and good separation effect.

2.3 Softening and tempering

The function of softening is to adjust the moisture and temperature of rice bran to make it plastic. Create favorable conditions for puffing. The softening temperature is generally 50 -80 ℃. At the same time, the softening time is generally about 20 minutes.

2.4. Puffing

After being softened and tempered, the rice bran enters the puffing machine for puffing treatment to strengthen the leaching effect and increase the output of the equipment. After the rice bran is subjected to a series of effects such as squeezing, kneading, shearing, pressure and other mechanical actions in the extruder, as well as a series of effects such as the moisture and heat effects of the injected steam, and frictional heat generation, the oil-containing cells of the oil are completely destroyed and the oil is fully exposed . At the end of the extrusion screw, the pressure and temperature of the material are very high. After the high temperature and high pressure material comes out of the hydraulic die, the pressure is suddenly relieved, the material expands rapidly, and the water evaporates quickly to obtain a loose, porous, and high-strength extruded material. .

2.5 Cool and dry

The expanded material enters the flap cooler for drying and cooling to improve the quality of the leaching material and improve the leaching effect

3. Extraction workshop

3.1 Process characteristics of leaching workshop

3.2 The leaching process is a large-scale production process, using a mature flat-rotation leaching device, DTDC steaming off machine

3.3 Meal foam system capture can effectively avoid the entrainment of the meal foam in the secondary steam entering the first long tube evaporator to ensure the heat transfer effect and evaporation efficiency;

3.4 The layout of the whole workshop is reasonable, generous and beautiful, convenient for operation and management.

3.5 The leaching is designed according to the flat-rotating leaching device, which achieves good contact between the solvent and the material and rapid draining. The embryo layer is completely extracted, which is very beneficial to reduce the oil content of the meal and the dissolution of the mixed meal. This extractor is designed with a material level controller The material level controller cooperates with the frequency modulation motor of the extractor to maintain a raw material bed with a certain material level. On the one hand, it can support the material and seal the extractor, and on the other hand, it can maintain the action of the frequency modulation motor of the overextractor. The material level of the extractor and the flow of wet meal sent to the desolventizer are balanced. In addition, this extractor has low power, stable action, low failure rate, no noise, low failure rate, and convenient maintenance. It is one of the advanced extractors.

3.6 The solvent gas enters the condenser, the condensate of all the condensers in the system is collected into the liquid pipeline, and flows into the solvent water separation combination box. The fresh solvent after the water separation can enter the extractor without heating or less heating.

3.7 The first steam and the second steam share a condenser, so that the lower solvent gas evaporated by the first steam and the higher solvent gas evaporated by the second steam will enter the condenser after being neutralized, which greatly reduces the load of the condenser and improves the condensation efficiency. The condensate is collected in the water distribution box, and the final non-condensable gas enters the tail gas condenser. After the one-step condenser, the non-condensable gas is fully absorbed and treated by the paraffin absorption system, and the exhaust gas is discharged.

3.8 After the condensed solvent enters the solvent tank, the waste water flows into the cooking tank and the steam injected by the negative pressure vacuum pump through the evaporation system is fully digested and discharged.

3.9 Wet meal enters the DT steaming machine from the inclined scraper conveyor with frequency modulation through the closed valve for desolvation drying and cooling treatment. The steaming machine used in this process digests and absorbs the advantages of the Crown Schumacher steaming machine and combines the domestic manufacturers to design a special desolventizing equipment. The material gate device is professionally designed, and the action is flexible and reliable. The desolubilization layer seals the special material to achieve the automatic control of the desolubilization house material level to ensure the constant desolubilization time and position of the wet meal.

tag : Rice bran oil processing equipment,rice oil machine

New technology of rice bran oil processing from China,Our company adopts the latest international rice bran oil processing technology. We have dozens of successful rice bran oil processing cases at home and abroad, and the processing tonnage is 10-1000TPD.